Myth Buster

Broad Spectrum Claims

Broad spectrum should mean what it implies!

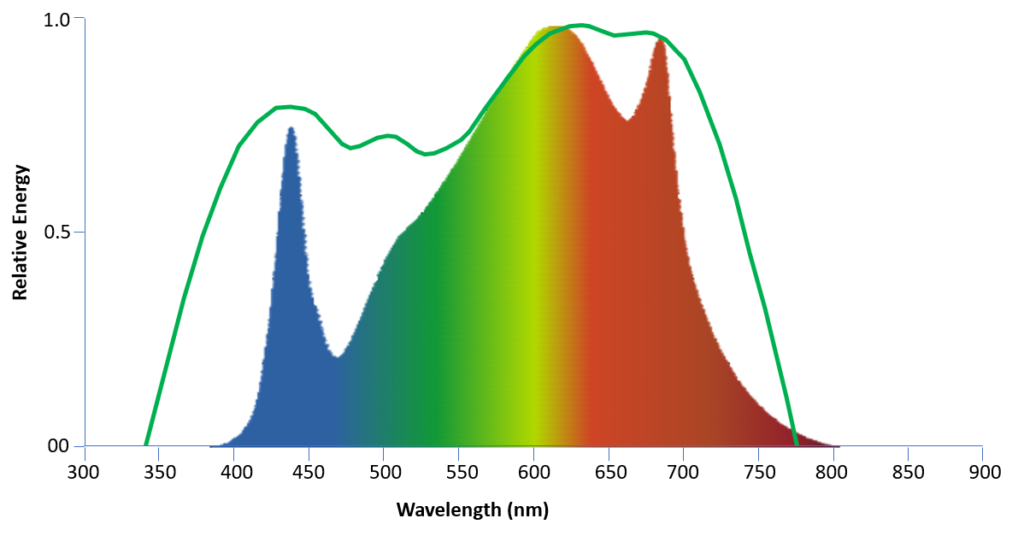

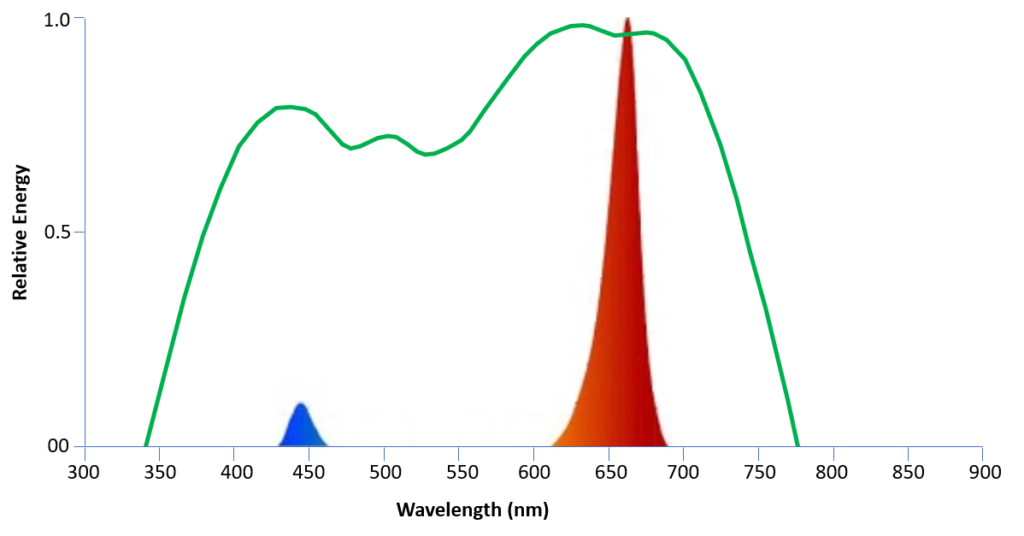

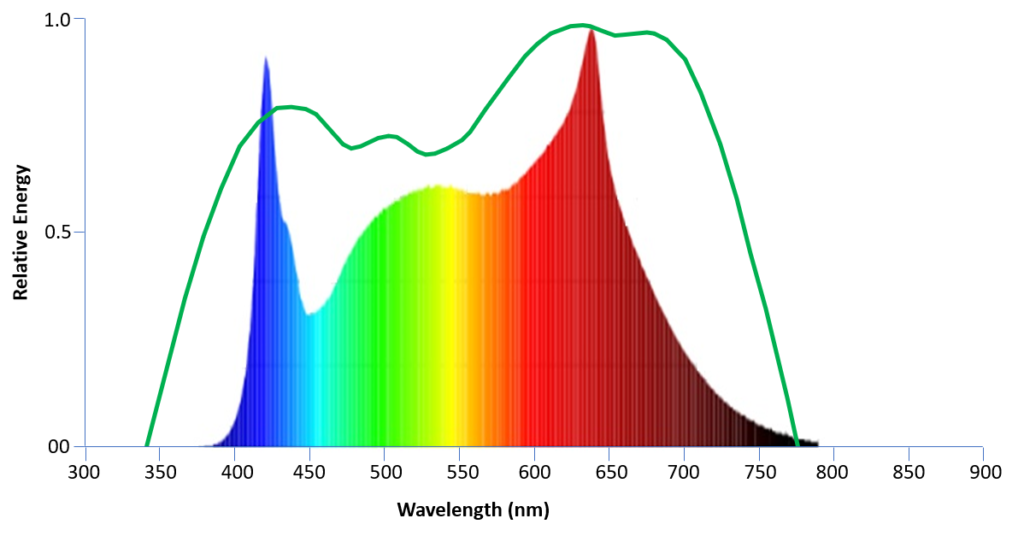

For a spectrum to be broad, having 5% green or white light added to a largely red/blue purple light DOES NOT constitute broad spectrum.

True broad spectrum would be classified in the 3000K to 4000K 80 CRI region.

There are variations of this that introduce enhancements in the 660nm region, 730nm far red region and sometimes the upper UV 380nm region.

Narrow Wavelength “Purple” LED Broad Spectrum based on 3500K CRI80 with enhanced 660nm Broad spectrum based on 5000K CRI80

What’s even worse is the use of the term full spectrum. Only the sun provides full spectrum!

LED Grow Light Myth: Any LED grow describing its spectrum as “full” is simply misleading you.

Broad Spectrum based on 3500K CRI80 with enhanced 660nm

Red / Blue (purple) LED Lights are not Broad or Full Spectrum

In a glasshouse, fixtures with a Red/Blue mix of LED diodes can be very effective (depending on the crop) because they have high efficacy and the plants benefit from the broad spectrum of natural sunlight.

For indoor grow rooms, a broad spectrum light is recommended.

A lot of LED lights on the market provide spectrum comprising 90 to 95% red and 5% to 10% blue 460nm LEDs to maximise photon efficacy of the fixture.

Plants have evolved over millennia in nature to utilise the full range of the light to drive photosynthesis, plant growth and development

Narrow band-width LED lights (i.e. fixtures with 95% red and 5% blue) do not optimise plant growth and development for fully enclosed environments where sunlight is not present.

Narrow Red / Blue Wavelength “Purple” LED

Broad spectrum based on 5000K CRI80

In a fully enclosed grow room or grow tent, broad spectrum LED lighting produces far better crop quality and yield than purple lights

As discussed elsewhere in this website, green light can penetrate further into the leaf than red or blue light which increases leaf photosynthesis.

The efficacy advantage of red /blue LEDs has also largely diminished. White LEDs based on a blue chip base are as efficient, if not more so, than red LEDs.

LEDs do not run "cooler" than other lights

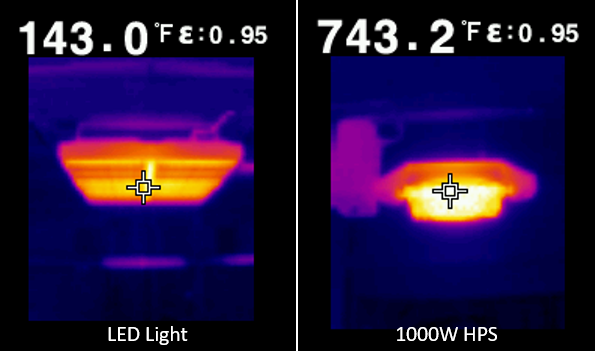

It is an LED grow light myth, and simply incorrect, to say that LED light fixtures produce less heat for the wattage that they consume.

LEDs do not run cooler than traditional grow lights such as HPS, MH, CDM or fluorescent but they are more efficient

This is because LED lights produce more lumens per watt (and more µmol/J) than traditional lights and therefore they use less watts of electricity to produce the same amount of light

Heat per watt of electricity is constant. Therefore using less watts results in less heat being generated.

A 650W LED can produce almost the same µmol/s as a 1000W HPS. The LED consumes 35% less electricity than the HPS.

1 watt of electricity produces 3.412 British Thermal Unit (BTU) of heat per hour regardless of light type incandescent, HPS, CDL, LED, fluorescent, induction, etc.

A 1,000W HPS grow light (1,060W with ballast loss) generates 3,617 BTU per hour heat. A 650W LED grow light (685W with driver loss) generates approximately 2,337 BTU per hour heat. The LED generates 35% less heat than the HPS.

British Thermal Unit (BTU) is the unit of heat energy. One BTU is the amount of heat needed to cool or heat one pound of water one degree Fahrenheit at a constant pressure of one atmosphere, equivalent to 251,997 calories.

HPS, MH and fluorescent radiate heat directly from their lamps and light reflectors also reflect the heat downwards towards the plants

LED chips are mounted on printed circuit boards (PCBs) which convects heat to a heatsink which in turn convects heat upward and away from the plant

As such LEDs can be placed closer to the plant canopy without scorching the leaves

The total thermal emission of the chosen lighting solution will influence the environmental conditions or your grow room or grow tent.

Plants need heat but too much heat causes stress and tip or leaf burn with higher evaporation resulting in more water usage

If the light generates too much heat then this has to be controlled through air conditioning which increases electrical costs.

The heat registers shown in the images were recorded for the 183W LED Light (on left) and a 1000W HPS (on right)

The LED Light offers a significant advantage over the traditional HPS in both light output, spectral composition and heat register

Surface temperature of a 1000W HPS can reach 800 deg F

LED Grow Light Myth - Max Power Rating is not its actual power draw

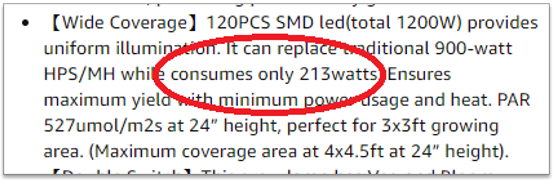

If a light fixture has 100 x 10W LED chips it is NOT a 1000W light.

This is the maximum theoretical power rating of the LED chips and they would never be capable of being run anywhere close to this level for the unit to function long-term.

All LEDs have a maximum rated theoretical power rating and then are run operationally at a level that is typically 15% to 40% of this theoretical rating.

An advert for a fan cooled LED light that claims 120 x 10W LEDs = 1200W will include in the small print that the actual power draw is about 198W which includes about 12 W of cooling fans. Remove the driver losses and we have a light fixture that is actually only a 175W light not a 1200W light. The light fixture built with these chips will emit closer to 1.6 µmol/J than the 2.5+ achievable with SMD fixtures.

If an advert does not declare the PPE (µmol/J) of the fixture then you know it is performing way below the standards that are available for similar price points on the market.

All LED diodes (chips) have a maximum rated power level

Power (watts) = forward current x forward voltage

For example, a 3030 LED diode could be theoretically maximum rated at 240mA and 6.6V DC meaning its theoretical maximum power rating is 1.584W

However, if the LED was run at this setting for any length of time it would get too hot, the light output would rapidly deteriorate and the diode would burn out and fail.

As such, all LEDs are operated at a much lower power setting, typically 15% to 40% of their maximum rating

Therefore a 3030 LED would normally be run at 65 mA and 6V DC = 0.39W to achieve maximum efficacy and lifetime (24% of the theoretical maximum)

It could be run comfortably at 120mA and 6V DC = 0.72W but would have a slightly lower efficacy

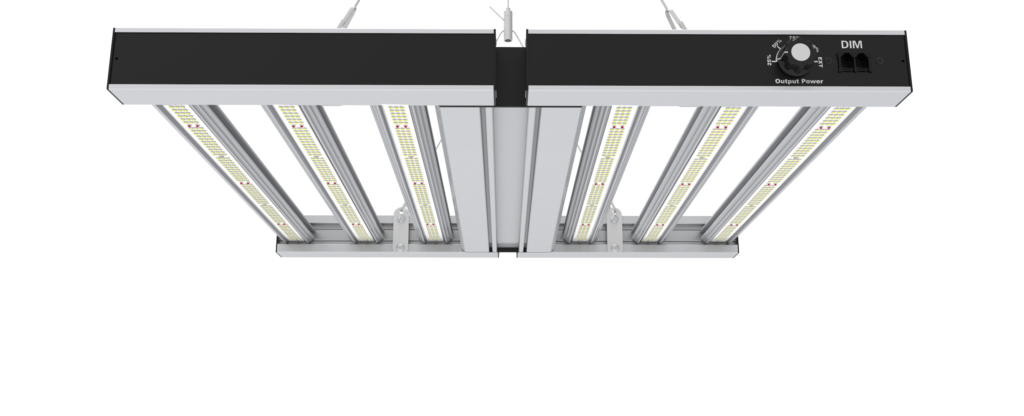

Most professional grade LED lights use 2835, 3030 or 5630 SMD LED chips. This is because these chips run at lower voltage and forward current and therefore have high efficacy. Lighting designers fit a lot of SMD LED chips into a light fixture to create high light output.

Some lights use 3535 or 5050 LED chips which are higher power (i.e. 6w to 10W maximum rating), but there efficacy is up to 40% lower than the SMD chips. Fewer chips are required to achieve higher power ratings for the lighting fixture but the µmol/J is lower.

Are fan cooled LED lights better?

A lot of the lower cost lights available on the market have fan cooling. This is because the units are built from a thin aluminium box with a PCB mounted onto the box with minimal heat convection properties. The fans are necessary to stop the LEDs from cooking and failing. However, if a fan fails then the light will quickly fail. Fans are electrically operated and if they are not waterproof fans, then moisture from the grow room will quickly get into the electrics and bearings of the fan and cause these to fail.

Passively cooled LED lights are the recommended solution.

PPFD is not a measure of light efficacy

Light efficacy (PPE) is the amount of light emitted totally by the light fixture. It is a measure of how many photons of light energy are emitted every second and the unit of measurement is µmol/J or is µmol/w/s

The PPFD number is the amount of light energy that hits a 1 m² surface at a specific distance from the light source.

The unit of measure of PPFD is µmol/m²/s

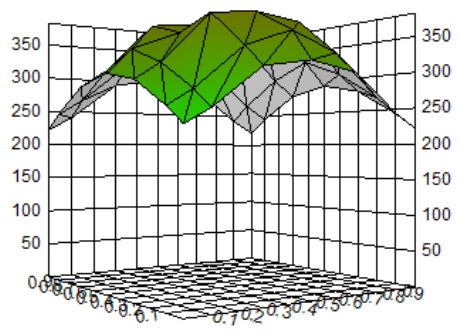

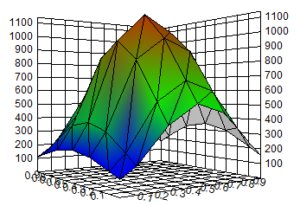

Any light source will have a higher PPFD reading directly below its centre line. The PPFD will fall away and reduce the further you move horizontally away from the centre line.

A light with no secondary lens will typically have a 120 degree or higher beam angle and will generate a wide spread of fairly uniform light.

A light with a secondary lens that focuses the light will have a high level of concentrated light in the centre with rapid drop off towards the edges of your grow area.

This can be misleading if a seller uses PPFD to try to present their light fixture as a high light producer. In reality, it provides high light in the centre but not enough on the edges.

Light efficacy is the amount of light emitted totally by the light fixture. It is a measure of how many photons of light To accurately measure the overall efficacy (PPE) of a light requires an integrating sphere that measures all photons of light emitted by the fixture.

To assess the likely efficacy of a fixture, it is possible to measure the PPFD on a flat 2m x 2m surface at regular grid intervals (say 10cm squares) and then to calculate the average PPFD of all measurements and divide by 10. A very rudimentary method but it gives some indication of light efficacy.

The distance the PPFD is measured from the centre of the light is also important.

As discussed elsewhere in this website the light energy reduces significantly the further you move away from the light source because its energy is diffusing over a wider and wider area

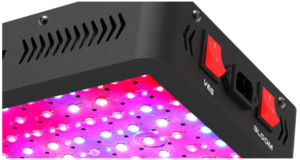

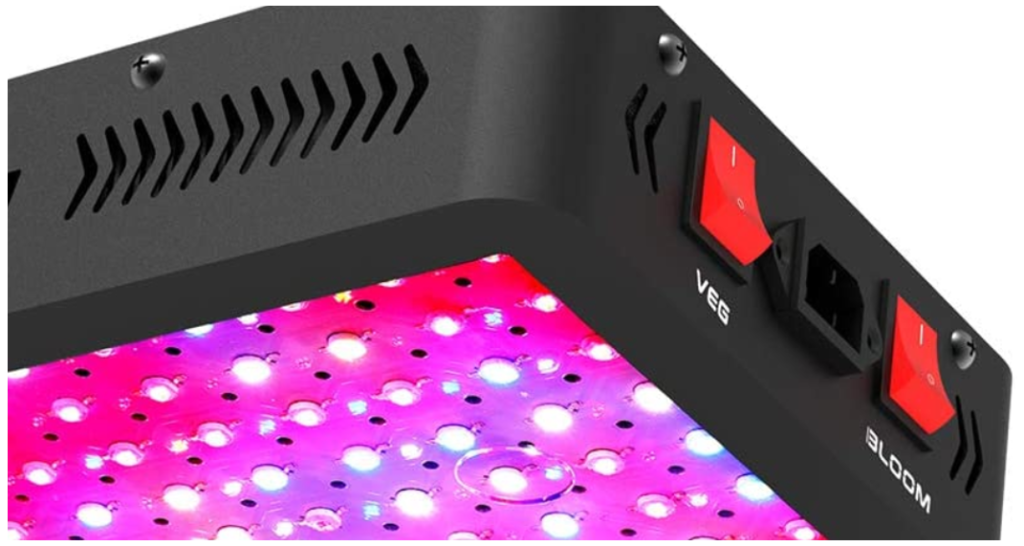

Are Veg and Bloom switches a bit of a Gimmick?

Veg and bloom switches do provide different spectrum of light for different stages of the plant growth.

However, a plant is reliant on light energy to photosynthesise.

As soon as you introduce a switch that turns off certain colours of LED to create a higher blue (veg) or higher red (bloom) spectrum then you lose significant light output.

Blue makes the plant shorter. Red makes it flower and stretch.

Buy a broad spectrum light with high efficacy.

Example, a 330W broad spectrum light from Fyntek will perform as well as a 600W HPS for all growth stages.

Beware non-waterproof lights

LED Grow Lights are suspended in hot, humid grow rooms and grow chambers

Water is circulating in water tanks, pipes and trays

LED grow lights that have a kettle lead for mains power, and a non-waterproof on-off rocker switch are not ideally suited for this environment

If they use cooling fans that are not waterproof then the fans will stop working after a while and the light will quickly burn-out

Be very cautious if you buy a LED grow light that is not waterproof.

High grade grow lights should be IP44 to IP66 rated.

This means dust and splash proof or water proof.

Be safe with electricity!

PPFD readings are not always what they seem

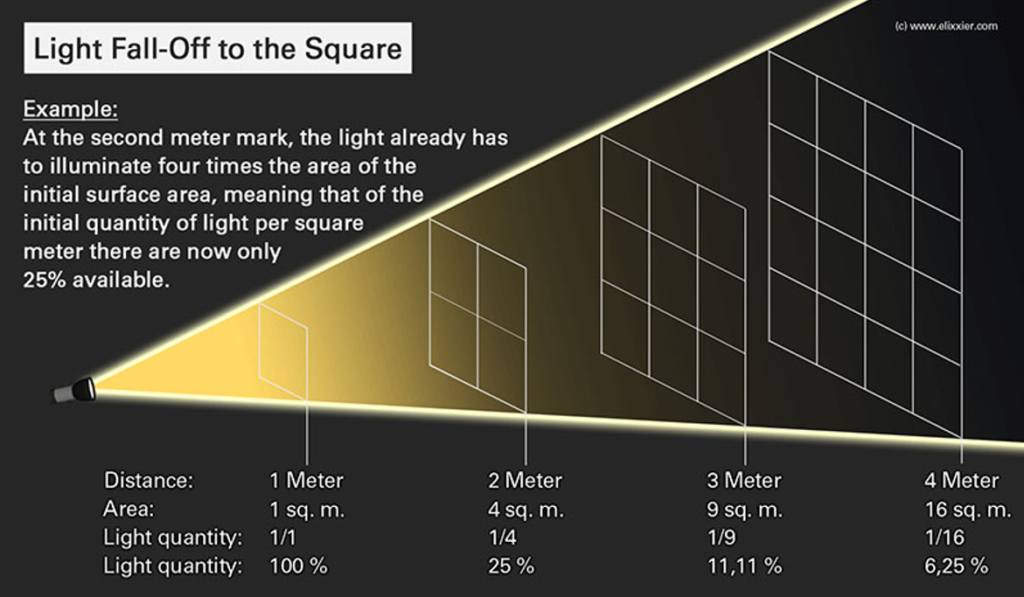

Light significantly reduces in intensity the further it travels from a light source.

If an advert claims 1890 umol/m2/s at 6” distance measured in the centre line of the light, it will only deliver 472 umol/m2/s at 12” and 209 umol/m2/s at 18”. At a typical grow light height of 24”, the light is delivering just 118 umol/m2/s.

This is because of the inverse square law.

Inverse square law = the light intensity at location A (subject area) decreases inversely proportional to the square of A’s distance to the light source (the fixture) – in other words, PPFD drops rapidly the further the distance the plant is from a single light source.

The true lifetime of a fixture

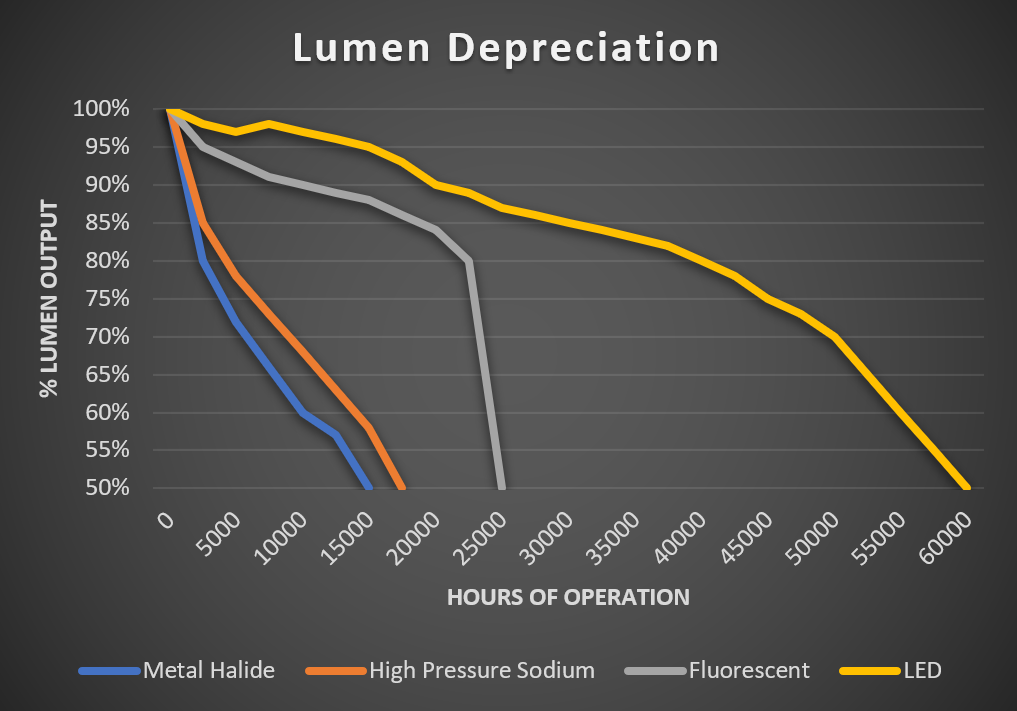

All artificial light sources deteriorate over time meaning that the light emitted reduces as the age of the light (the number of hours used) increases

LEDs retain a high level of light output in excess of 90% over a 40,000 hour+ usage range

HPS and MH Lights drop below 90% efficacy in excess of 5 to 8,000 hours usage meaning a lot of lamp replacements or reduction in light and growth.

You will need to replace your HPS and MH lamps every 2 years to retain sufficient light levels

F.A.Q.

if you cannot find the answer to your question then please send via contact page

LED chips emit light forwards away from their surface. They have a natural beam angle of between 120 and 180 degrees and will have a higher light meter reading immediately below their centre. To achieve a more even light meter reading on the edges of your plant you can raise your light higher away from the plant.

This is due to what is known as the inverse squared law. This is where the light intensity drops away inversely proportional to the square of the distance to the light source. It is because as you move away from the light, the same amount of light spreads to cover a bigger area.

Only the sun can provide a full spectrum of light. LEDs can provide a broad spectrum that covers a lot of the PAR curve but what you describe is essentially a narrow spectrum red/blue light with some green broader spectrum but not really sufficient to achieve optimum growth.

A good quality LED will generate more photons of light per electrical watt of power consumption than an HPS. As such, an LED that draws 600W electrical power can perform at similar light levels to a 1000W HPS. Each watt of electricity generates the same amount of heat regardless of what it is powering. Therefore LEDs don’t run cool, they just need less electrical power to achieve similar light output to an HPS.

A 213W LED will not be a match for a 900W HPS. The general rule of thumb is that a good quality LED, achieving 2.5 umol/m2/s or higher, will match a 1000W HPS if it draws 600W or more. If you bought an LED grow light that was advertised as a 1200W light but in reality it only daws 213W, then the reference to the 1200W is only the theoretical maximum rating of the LED chips.