Traditional Grow Lights

Introduction to Traditional grow lights

There are a number of different lighting solutions that you can purchase for your grow room which we have categorised as “traditional grow lights” and “LED grow lights”

There are 4 lights in this group that have been in use very effectively by growers for many decades.

Metal Halide (MH), High Pressure Sodium (HPS), Fluorescent or Compact Fluorescent (CFL)

The technology for these lights was first invented in the early to mid part of the 20th century and the technology has evolved little over the past 30 years.

They come from a technology family called gas-discharge lamps that generate light by sending an electrical discharge through an ionized gas

MH and HPS are high intensity discharge lights (HID)

Fluorescent and CFL are low intensity discharge lights

These traditional lights come in different power levels:

- High Pressure Sodium (HPS) and Metal Halide (MH) Lights : typically 400W, 600W or 1000W

- Ceramic Discharge Metal Halide (CDM) : typically 315W or 630W

- Fluorescent Tubes : typically T5 28W for 4ft (1,200mm) length

Typically these traditional grow lights consume a lot of electricity and therefore heat in the process of generating light

Efficacy ranges from 1.3 for fluorescents to 1.8 for HPS

MH have a higher blue content than are typically used to generate vegetative growth

HPS have a higher low red and infra red band and are typically used to generate flowering stage of plant growth

Fluorescents have a high blue content and are are typically used for propagation of plants

All of these traditional lights were developed to improve the visual capability of human in general warehouse, street light or workshop / office use

Their spectrum are not ideal for plant growth but a large proportion of the light they emit falls inside the PAR range

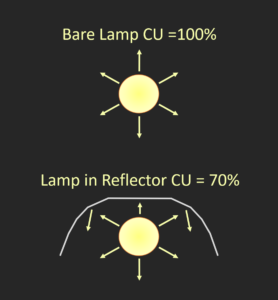

All are omni-emittance and emit light 360 ° from their lamps – coefficient of utlisation (CU) reduces efficacy All have high levels of light degradation after only a short run-time

Frequent lamp changes are required to maintain efficacy or lower plant growth – this is the choice of the grower

Ballast efficacy deteriorates over time

Fluorescents optimal operational conditions are 35 deg C and below this the light output deteriorates.

All are available at relatively low cost for good quality lights

HPS and MH are hot – as high as 800°F on the housing

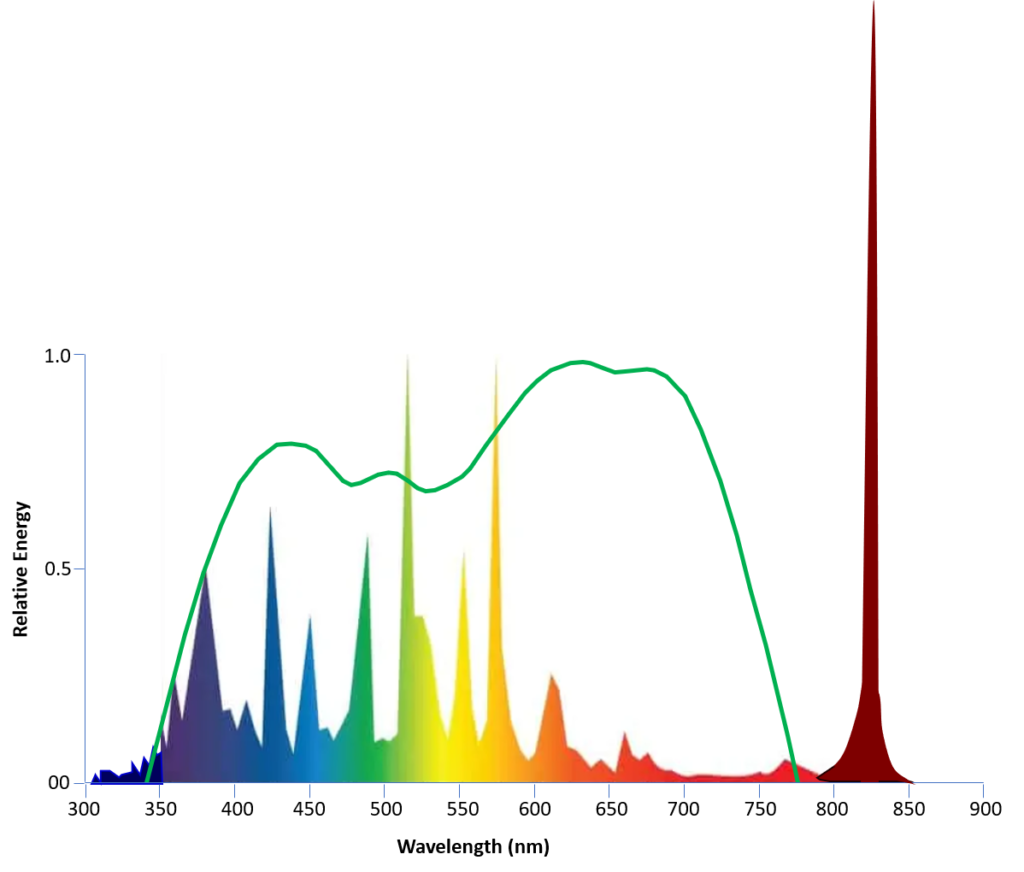

Metal Halide

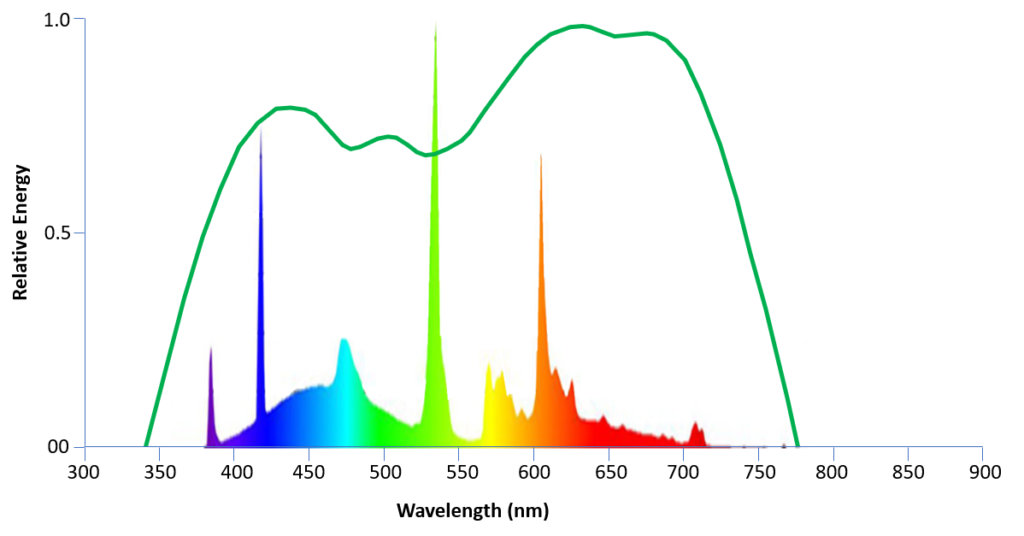

MH lamps have a blue-biased spectrum that makes them ideal for vegetative growth

With approximately 30% blue in their spectrum they produce compact plants

They generate approximately 1.29 to 1.43 µ/J from a lamps thate range in output from 250W to 1000W

The MH fixture typically has a power factor of 0.92 meaning it consumes approximately 1085W when fitted with a 1000W lamp

The blue spectrum from 350 to 460nm results in strong vegetative and root growth

The MH has insufficient light in the red spectrum making it unsuitable for the flowering stage

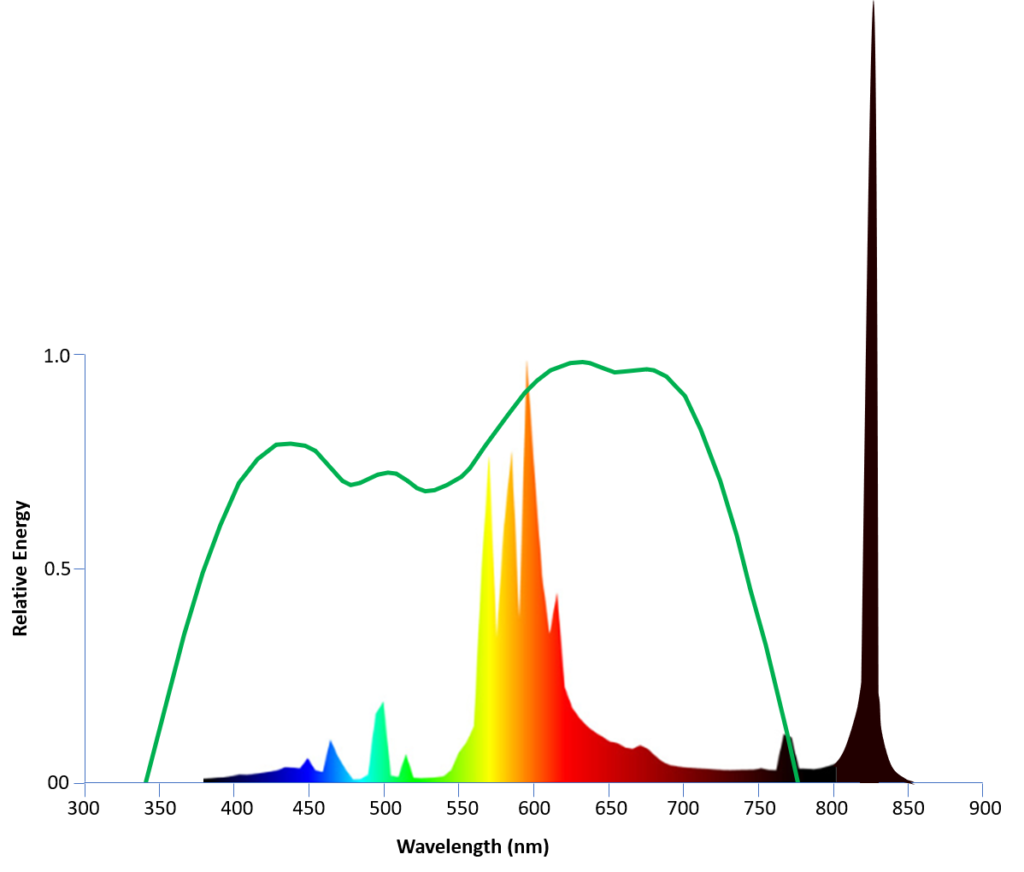

MH lamps emit a high peak of infra heat light in the 830nm range

Ceramic Discharge Metal Halide (CDM) or Ceramic Metal Halide

CDM lamps have a broad spectrum that also includes UVa and low infra red

They generate approximately 1.95 µ/J from a 315W or 630W lamp (i.e. 614 µmol/s to 1,228 µmol/s total output)

Pricing is similar to some high power LED lights available on the market and as such, the $ per µmol is poor

The CDM fixture typically has a power factor of 0.95 meaning it consumes approximately 331 or 663W

The blue spectrum from 400 to 460nm results in strong vegetative and root growth

The CDM lacks sufficient red to make this ideally suited for generating high yields during the flowering stage of growth.

As such, CDM lights are ideal for the vegetative stage of the growth cycle

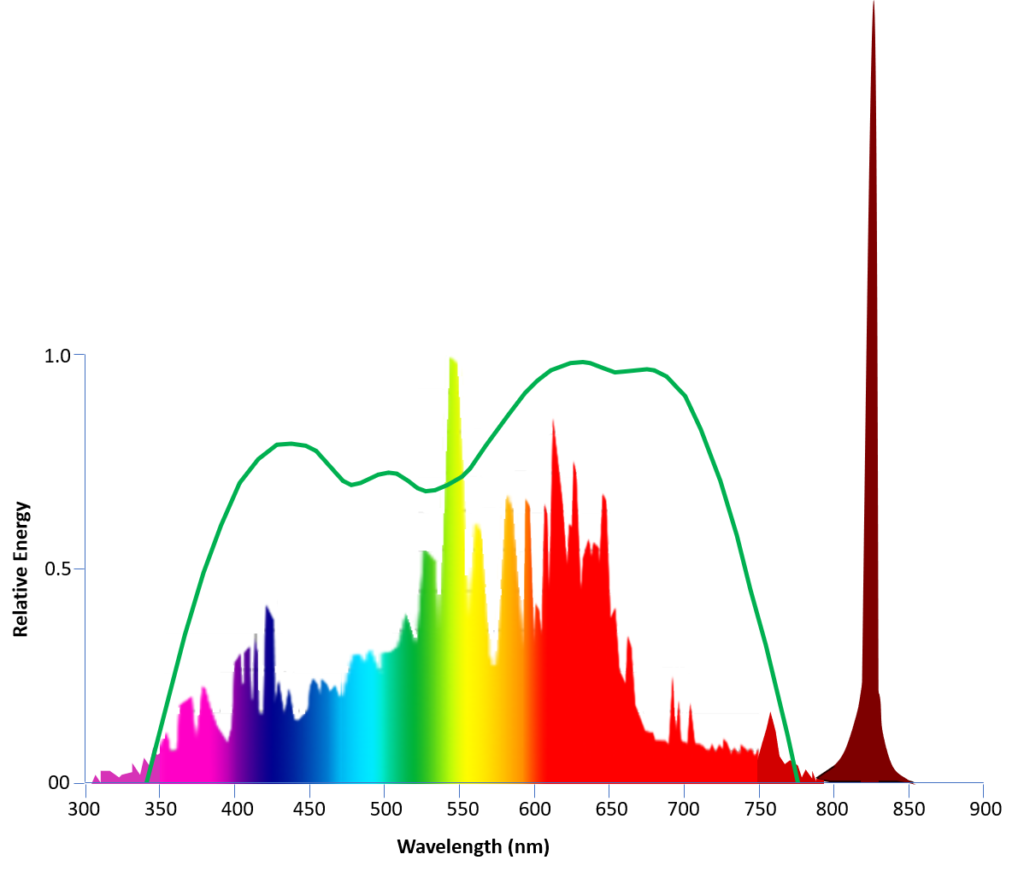

High Pressure Sodium (HPS)

HPS lamps are an efficient light source

They have very little blue in their spectrum (approx. 4%) with the majority of light emitted in the 560nm to 610nm range.

With high photon output in the yellow to low red range, they are efficient lights for flowering

They generate 1.85 µ/J from a 1000W double ended lamp (i.e. 1,850 µmol/s total output)

The HPS fixture typically has a power factor of 0.94 meaning it consumes approximately 1,064 W

The spectrum has very little blue light, is dominated in the 560nm 610nm region (yellow to low red), has a small spike of 760 to 765nm far red and a large spike of infra red from 810 to 830nm.

Lacks ability to enhance cell production for root or vegetative growth.

Lacks 430 to 450nm and 640 to 660nm which is most efficiently absorbed by chlorophyll a and b

Contains high infra red register in 760nm and 830nm range which results in fast flowering, taller and more stretched plants.

Not an all-round grow light but HPS lights are ideally used for the flowering stage of the growth cycle

Fluorescent Lighting and Compact Fluorescent Lighting (CFL)

Fluorescents have been used as plant grow lights for many years predominantly in tiered or shelved vertical growing systems or as germination and propagation lights.

They have very poor photon efficiency and generate approximately 1.3 µmol/J depending on make and environment (CFL’s are even lower at a µmol/J of about 1.08)

The ideal operating temperature for T5 fluorescents is 35°C whereas most grow rooms operate in the 20 to 25 °C range.

At this temperature, fluorescents are only operating at between 80% and 90% of their optimum and therefore efficacy is reduced to between 1.04 and 1.17 µ/J

Fluorescents are available in different lengths but the 2ft (24W) or 4ft (54W) tubes are mostly used for plant growth. Power factor is about 0.95 resulting in a power drawer of 25W and 57W respectively.

The spectrum has a lot of blue light which is why they are ideal for germination and propagation where root growth is important but they lack a broad spectrum light with sufficient power to be optimal growth lights.

Fluorescents also emit light in the upper UV range

Pros and Cons of traditional grow lights

In terms of traditional grow lights there are a number of pros to consider:

Firstly, they are well known and trusted grow lights for many growers world-wide

A lot of growers and farmers who use these lights achieve very good yields

High energy usage can be addressed through the addition of renewable energy sources

Radiant heat generated by the lights helps to increase the surface temperature of the leaf which increases transpiration and therefore uptake of water and CO2

Excess heat produced by the lights can be re-cycled and used elsewhere

Purchase price is still relatively low and offsets the high running costs

Cons to consider:

High running costs

Lamps need to be changed every 2 years or they lose significant light output

Plants cannot be easily inspected for diseases or health because the CRI under HPS is very low (not an issue for CDM or MH)

Low efficacy compared to LED

High heat generated in the grow room which needs to be removed

F.A.Q.

if you cannot find the answer to your question then please send via contact page

In terms of light output per $ or £ then yes. However, the spectrum of an LED is better and LEDs use less power to achieve the same light output resulting in lower heat.

HPS lamps lose light output very rapidly in the first 100 days of use and then continue to fairly moderately decline in terms of output after that. As such, you should consider changing your lamps every 2 years otherwise you are getting poor light output but still using a lot of electricity.

Fluorescents are effective grow lights but LEDs are way better when it comes to light output, spectrum and power usage. A little known fact is that fluorescents perform best at about 35 deg C (95 deg F) which is way too hot for a grow room and they should be “run in” when first used by only using for short periods of time. Running at lower temperatures and using for long hours straight out of the box will reduce light output a lot.

Sadly not. the efficacy of a metal halide is lower than an HPS and as such a lot lower than LED. Also the spectrum is heavily blue biased meaning they are ideal for the veg stage but not for full-cycle growth.

CDM do have a good plant growth spectrum and their efficacy is a little bit higher than an HPS, but they cost as much as an LED and are still 30% lower in efficacy than a broad spectrum LED.